8 Points to pay attention when purchase printed masks packaging bags

Printed Packaging Bags for Masks

Due to the spread of the epidemic, surgical face masks have become a vital anti-epidemic material. More and more clients are trying to make a contribution to providing this product to more folks, enabling people to protect selves from the virus. As people’s requirements for the mask are constantly getting strict, extra high-quality mask packaging bags, therefore, become essential.

Good quality packaging bags can, on one hand, protect the surgical face masks well, on the other hand, stand your brands out from your peers. To help our clients choose suitable printed pouches, we share below useful tips with you:

8 Points to Pay Attention to When Buy Printed Pouches for Masks

1. Packaging bags able to protect the masks

Face mask packaging bags need to basically ensure and maintain the technical properties required by the mask, such as breathability, chemical stability, physical and mechanical properties like integrity (measured with a seal tester). So the masks packaging bags have to be sealed after packing 100% to avoid pollution. And better a light-proof lining added to protect the masks from strong light during transportation and storage.

2. Suitable for the mask production process

Qualified face mask printed pouch bags can meet the requirements of mechanical packaging and auto packing during the production process of masks.

In addition, masks printed pouches should also be able to go through sterilization, meet 100% sealing to ensure surgical masks quality.

3. Do remember to show how to wear the masks properly

Instructions on how to properly wear the masks are essential. In this way, with simple words and images printed on the masks packaging bags, end consumers are able to read and imitate, especially to the kids.

Instructions as below to inspire:

4. Good masks packaging bags promote sales

Printed pouches for masks with descriptions and details on grades of masks, tips to discard, application scenario of masks and how-to-use, will present a better impression to the consumers. It helps to increase the user experience and make your supplies more competitive in the market.

5. Health and safety

No odor and pollution of harmful ingredients, to ensure the hygiene and safety of the mask. That is also why brand new raw materials have to be used during production.

What’s more, most surgical face mask packaging bags are packed in disposable bags. However, it is better to add a resealable zip lock on the top. For the reason that the left masks can be kept well in good sealing.

6. Cost-efficient mask packaging bags

Mask packaging bags are mostly disposable. So you can consider what thickness to use to save cost and be more eco friendly.

- 50 micron

- 70 micron

- 100 micron

- 120 micron

7. Commonly used materials

Commonly used materials for mask bags are MOPP, PET, CPP, LDPE, aluminum foil, etc. You can choose between a single-layer mask bag or multiple-layered-structure.

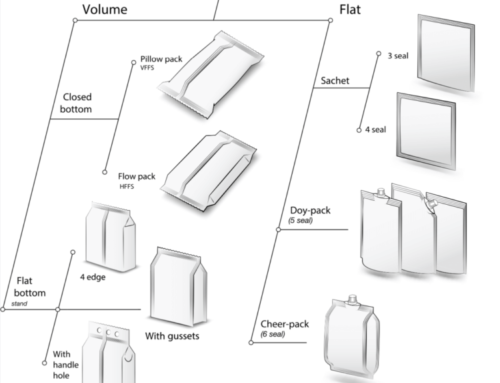

8. Popular bag styles

Stand up pouch or named doypack and 3 side seal pouch are two popular packaging formats to choose from. You are also welcome to contact us for more cases sharing.

Well, if you want to know more, feel free to contact us via [email protected]. Our sales will respond to you in minutes.

Oh, want to know the lead time? Cause you are in a hurry? No problem, we have digital printing to finish 100000pcs in 9-12 days.

Contact us now!

Leave A Comment