Food packaging bags play a crucial role in the marketing and use of food products. So, what are the commonly used materials for food-grade packaging bags? Here are: aluminum foil, nylon, polyester, polyethylene terephthalate, etc.

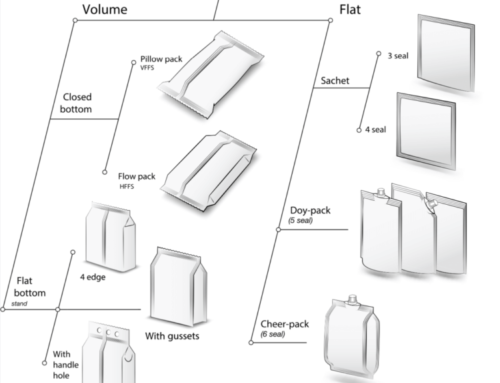

Food packaging popular structures:

To increase the performance of food packaging bags, food packaging materials are laminated into a multi-layered structure. As below, popular structures are:

- MOPP/VMPET/PE

- MOPP/KRAFT/VMPET/PE

- PET/VMPET/PE

- PET/PE

- PET/CPP

- PET/PA/PE

- PET/AL/CPP

- PET/PA/AL/CPP

- PA/AL/CPP

- PA/PE

- PA/CPP

Wow, there are too many options, and I have no idea what this jargon means. What should I do?

No panic, friend, take it easy. One simple glance is enough. Because we will help to offer you the solutions according to your specific products.

Common properties of food packaging materials:

……. Can you please say it in human language? Simply put, what are the differences?

OK, ok, briefly speaking, for your easier and better understanding the characteristics of commonly used food-grade packaging materials, remember this:

- PE or also said as LDPE is suitable for low-temperature use while CPP is more suitable for high-temperature use.

- PA or also said as Nylon is to increase physical strength and puncture resistance.

- AL, no matter it is pure aluminum or just foil, is to increase the barrier performance as well as lightproof or shading;

- PET is to increase mechanical strength and has excellent stiffness.

Better Barrier Properties:

In addition, food-grade packaging materials should have better barrier properties. Especially,

- Fatty foods require higher oxygen resistance and oil resistance.

- Dry foods require higher moisture resistance to ensure shelf life.

- Aromatic foods require higher smell proof properties.

- Fresh fruits and vegetables require packaging to be of high oxygen, carbon dioxide, and water vapor permeability.

More food packaging bags characteristics:

What is more, better tensile strength, tear resistance, impact resistance and excellent chemical stability (no chemical reaction with the food inside) are essential as well.

At last but not the least, a higher temperature adapted material will be able to meet the requirements of high-temperature disinfection or low-temperature storage.

If it is still hard for you to have a clear image, don’t hesitate to contact us.

+86 1857 1566 509 on WhatsApp/WeChat/mobile

Leave A Comment